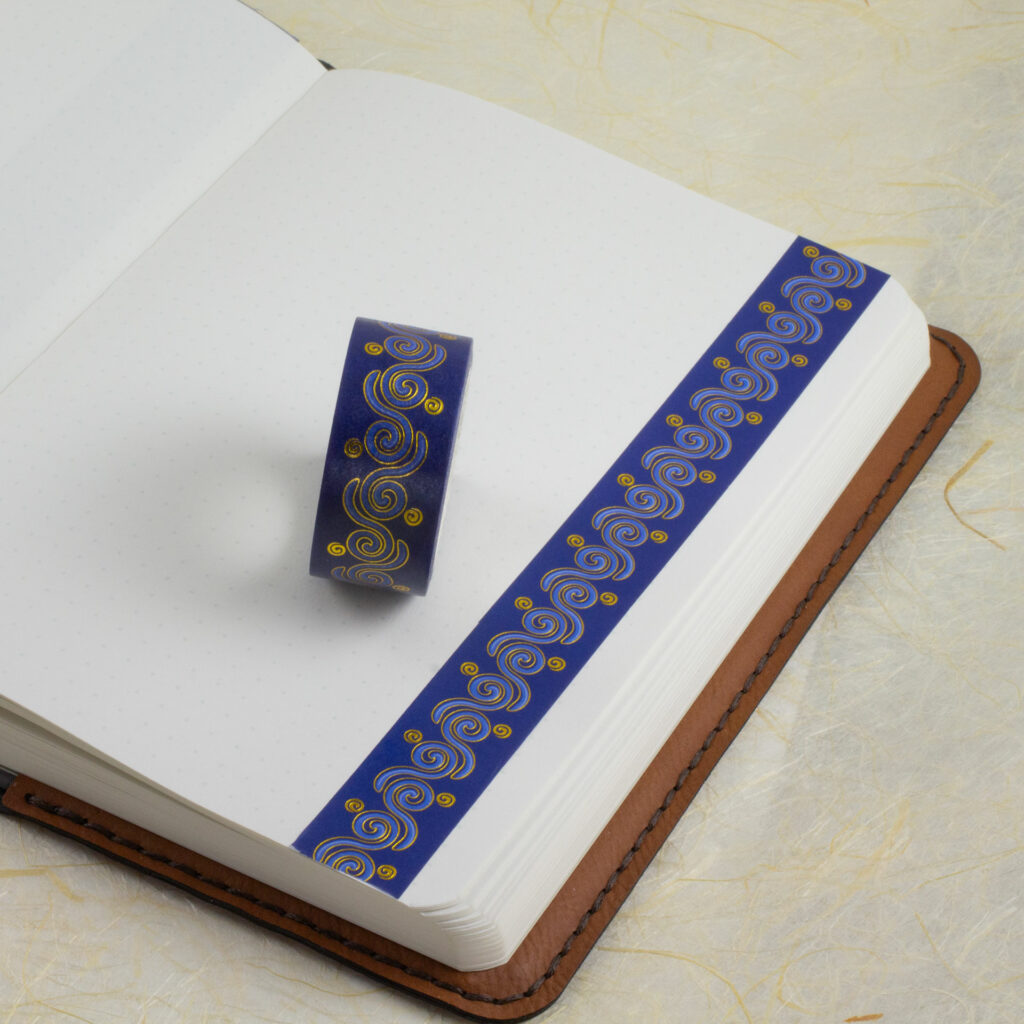

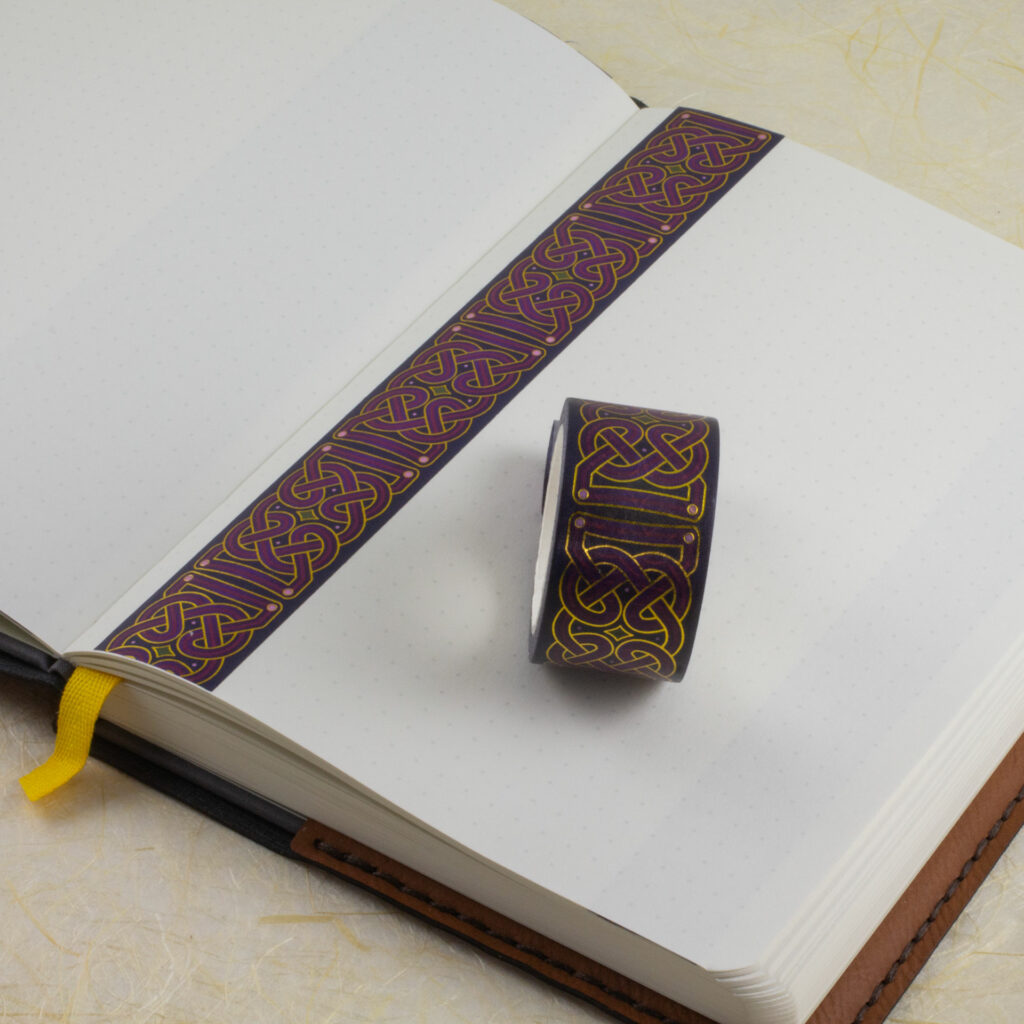

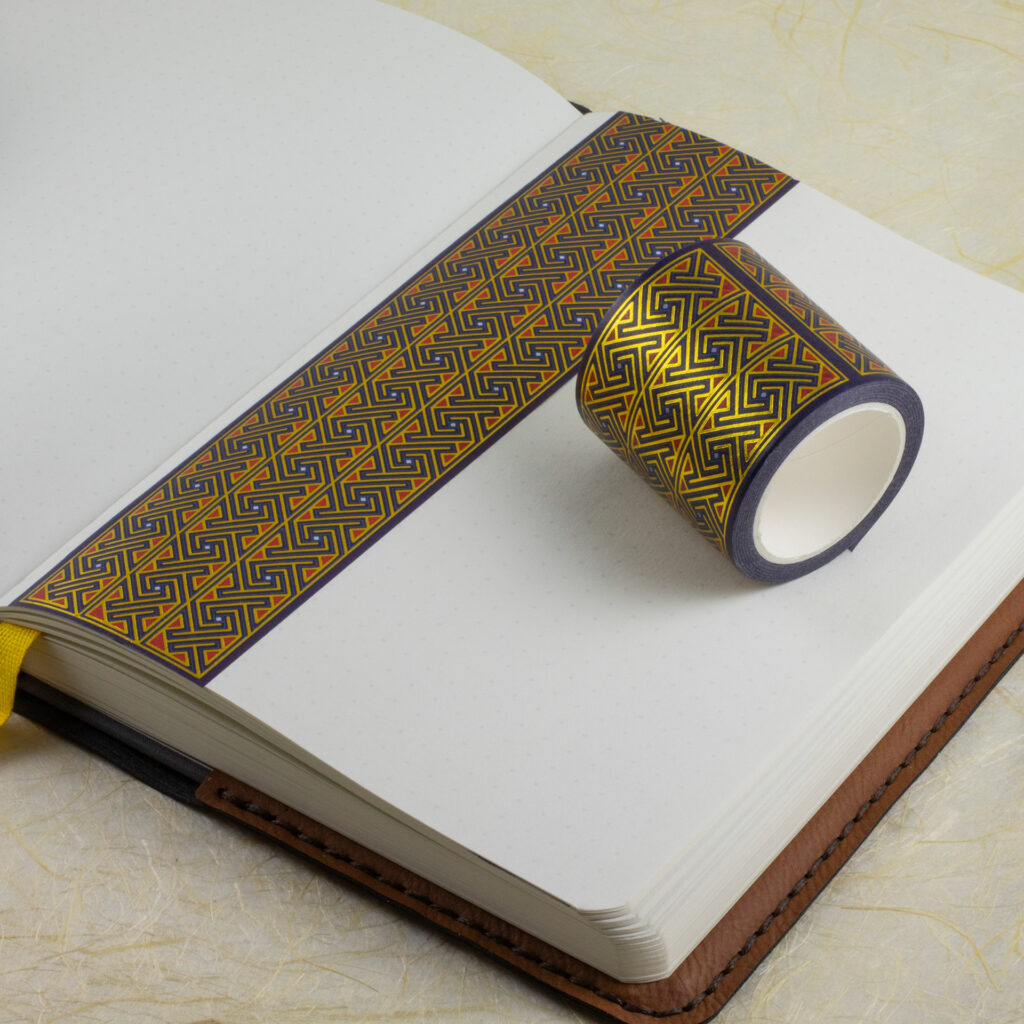

More Celtic Art Washi Tape

I couldn’t resist designing some more Celtic art washi tape. I did another key pattern, much wider this time (45mm), in purple and red (with some pale blue accents). I made a variant of my Spirals design (similar to the Spiral Flow fabric I did) in shades of blue. I also did a riff on a classic Celtic knotwork/interlacing design in shades of purple (with a green accent). All have gold foil outlines and accents.

If you are into it, I made enough to share. The new washi tapes are up in the shop, individually and in a discounted bundle.

Chibitronics Intervew

Chibitronics interviewed me for a Meet the Maker feature on their blog! If you want to know more about me, my background, my process, and what I do, check it out.

Purple Twist Top Box

After making hardwood gift boxes for the 20-sided dice I made to give as holiday gifts, I decided they needed an additional wrapping to protect them, and to create a reveal for the wooden boxes. I cribbed the closure for this box from a classic Japanese product packaging design. The Celtic knot on the sides is the same one I used for the silver medallions on the wooden boxes. These were cut on the laser from the dwindling supply of large sheets of the “Curious Skin” stock.

Folding and spin video:

Hex Chonk Box

I have been making some 42mm Jesmonite 20-sided dice (D20s) this year to give as gifts to friends and family. Early on, I had an idea for making gift boxes for them. I have been wanting to do an actual full project on the desktop CNC machine [previous CNC experimenting], and this was a good opportunity.

I spent a lot of time thinking and planning, but the actual project came together pretty quickly over the course of a week or so.

In addition to working with the CNC, I dug out some silver metal clay (PMC) I have had, and intended to do more with, for about 20 years. Using new skills gained from making the dice, as well as old skills modeling Celtic knots in 3D, I was able to make a mold and cast some medallions for the box tops from silver clay.

There are a couple more partly completed for my own collection, including one with a copper clay medallion that I will likely share when it is finished.

If you want to get a good look at them from different angles, here are some spin videos:

There is, of course, a whole process video of making the boxes:

D20 Chonks from Scratch

I kept thinking I wanted to get a little more experience with mold making and casting. I have nieces, nephews, and friends who are all playing various tabletop roleplaying games (TTRPGs) like Dungeons & Dragons regularly. Dice would make great gifts for all of those people. I have also been enjoying the work of some of the resin artists I have found making dice. I didn’t really want to do a bunch of resin casting in my home studio, but had become aware of some less-toxic stone-based “eco resin” casting materials like Jesmonite.

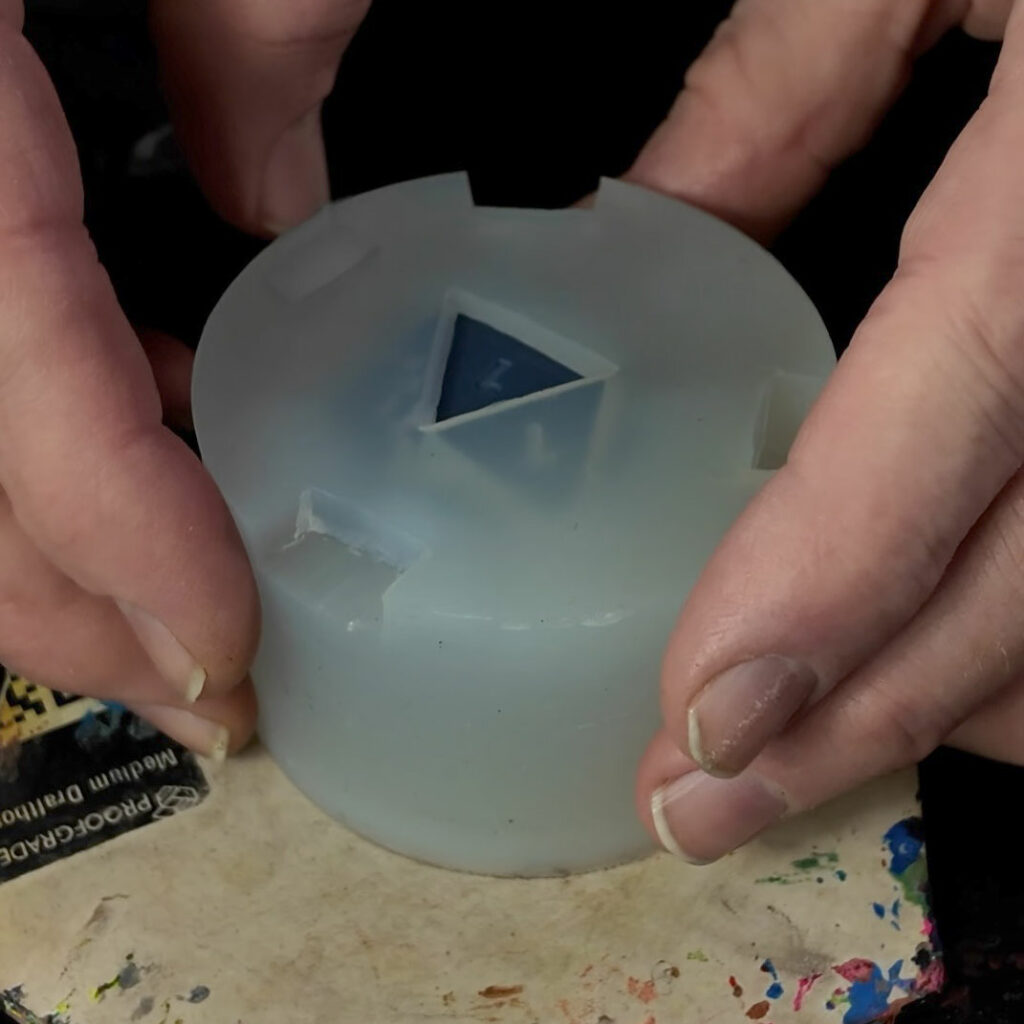

Back in March, I started working on making a big 42mm 20-sided die (a D20, in TTRPG parlance). I modeled it in Blender with a font I like (and have properly licensed), and set about 3D printing one from which to make molds. Although I have been knocking out all sorts of perfect models on my resin printer, there were some issues with getting my Anycubic machine to produce a flawless D20. At first, it was mechanical. It took me a bit to realize the plate had worked itself loose in a way apparently isn’t expected, then a bit to get it fixed correctly. Minor issues after that were eventually resolved by choosing the right resin.

From that print and a printed mold form, I made silicone molds, eventually coming up with a slightly-modified cap mold style that seems to work pretty well.

I cast a bunch of dice in Jesmonite, playing with various mixing and pouring techniques, different pigments, and various approaches to keeping bubbles and voids from ruining the casts. I mostly settled on using an old dental vibration table, some tapping and stretching of the filled molds, and a pressure pot for the later.

I have been painting in the numbers with acrylic paint, and finishing by polishing with bees’ wax.

There are a lot more finished dice than I am showing in this post. I haven’t managed to photograph all of them yet. I may add more in the future.

Once I had some big dice, I decided I needed to make some cool gift boxes for them. That’s for another post, though.

I made a video walking through the journey of getting some finished Jemonite chonks:

You can also watch some of them spin in the demo short:

Double Spiral Chocolate Bar Box

I needed to wrap this fancy chocolate bar, and decided to design and fabricate a custom box for it. Designed in Inkscape, cut on the laser from the violet Curious Skin cover stock.