Quick Celtic Key Square Print

I made some quick-and-dirty Celtic key square relief prints with a rubber plate engraved on the laser.

Here is a video with the whole printing process.

180° Degree Spirals Pop Up Card

Laser-Scoring Both Sides of a Card

I have had several people ask me about this. So, I made a video showing how to score both sides of a piece of paper or card stock with precision alignment using the laser.

After cutting and scoring the front of the card, I cut an outline of the reversed card and, set up a simple right-angle jig to make it easy to put the cut cards in the same spot in the machine. I discuss several methods for work hold-down and, how to adjust for minor errors in the setup.

I am consistently able to get hair-line alignment using this approach.

While I am using a Glowforge here, this technique is essentially the same in other laser cutters.

Resources

Glowforge Boot (for reducing tray movement)

Acrylic Square / Fiducial Alignment Ruler

(While this incorporates fiducial markings for a beta alignment feature you may not have (Snapmarks), we are NOT using that here. We just need a right angle piece that will stay put and, let us consistently put our cards in the same spot in the machine.)

Amazon referral links for some parts and incidentals defray IT and hosting costs for a local arts organization (Arizona Aikido).

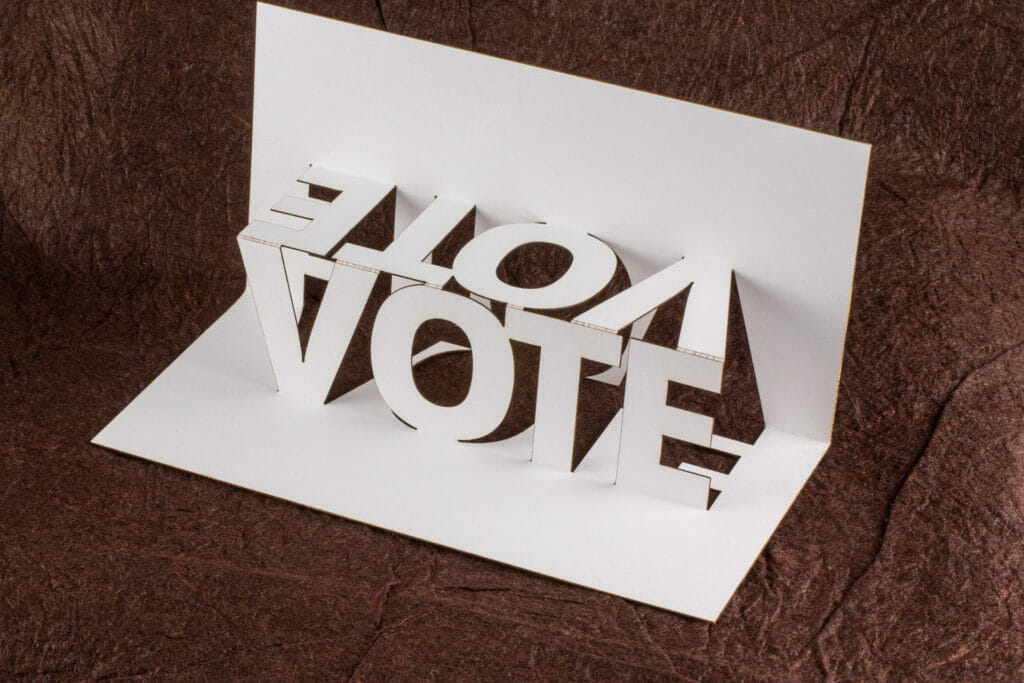

Pop the Vote

There is a big event going on in the United States right now.

If you would like to make your own, you can download the Pop the Vote pop up card pattern for free.

Totoro Twisted-Crest OA/Kirigami Pop Up Card

Just open this card and … 🎶 you’ll be meeting Totoro! 🎶

Although I don’t normally do a lot with other people’s characters or designs, some of Hayao Miyazake’s movies have a special place in my heart. I know they do for many others, too. So, I did this for some upcoming birthdays.

I sketched my Totoro (Totoros?) in Procreate on the iPad, with a still from the movie as a reference. I used the sketch as a reference to make a vector version in Inkscape. I created the ferns the same way. I designed the flowers directly in Inkscape.

Engraving wasn’t providing enough contrast, even when dusting with chalk. So, the white on the fronts are polyester sticker stock where I just cut the sticker layer and weeded it. I filled in the tail engraves with a white gel pen.

Celtic Key Patterns

Celtic key (or maze) patterns figure prominently in a few past and a bunch of upcoming projects. So, I made a quick video with some basics on how I assemble those as vector art images. I used Inkscape for these but, the principles are the same for any vector art program.

Celtic Art: The Methods of Construction by George Bain

Celtic Key Patterns by Ian Bain

Celtic Pattern: Visual Rhythms of the Ancient Mind by Adam Tetlow

(Proceeds from associate links defray hosting costs for a local arts organization, Arizona Aikido.)