Depthmaps Straight from Nomad Sculpt

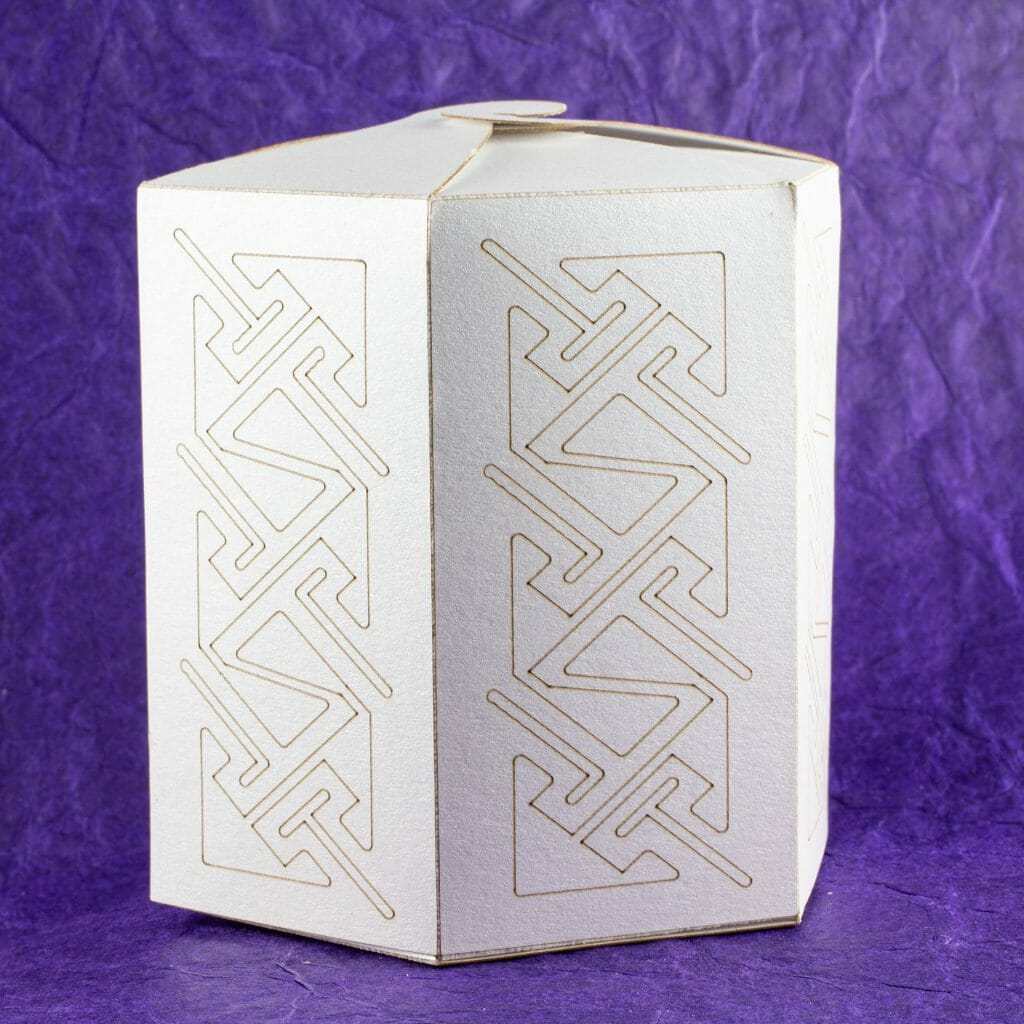

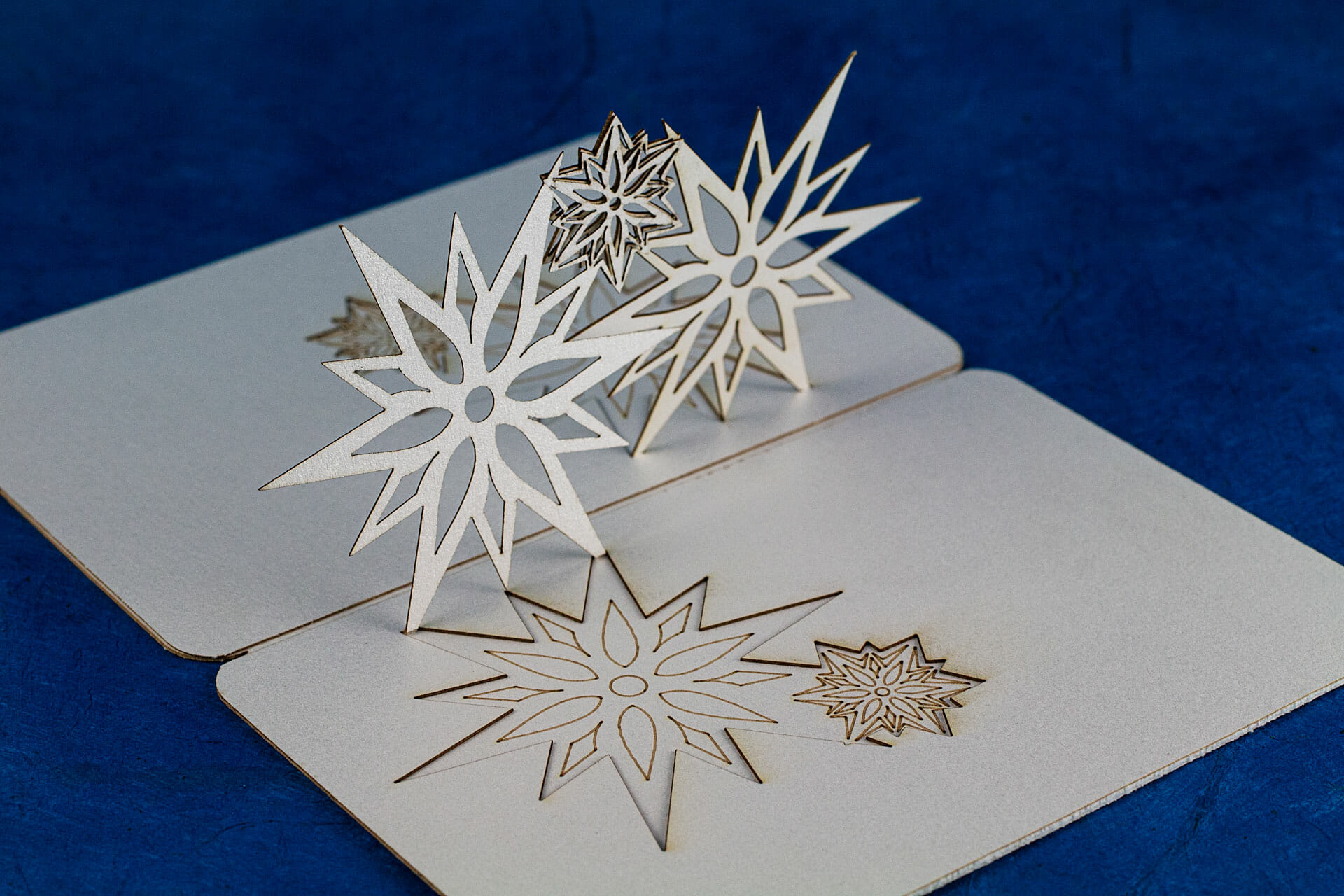

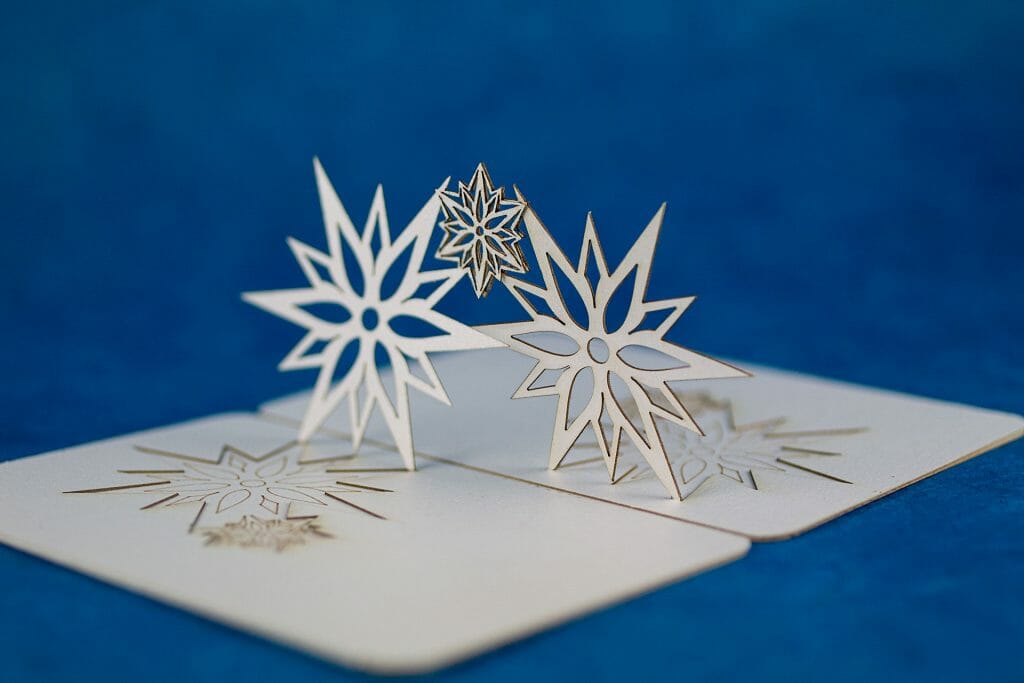

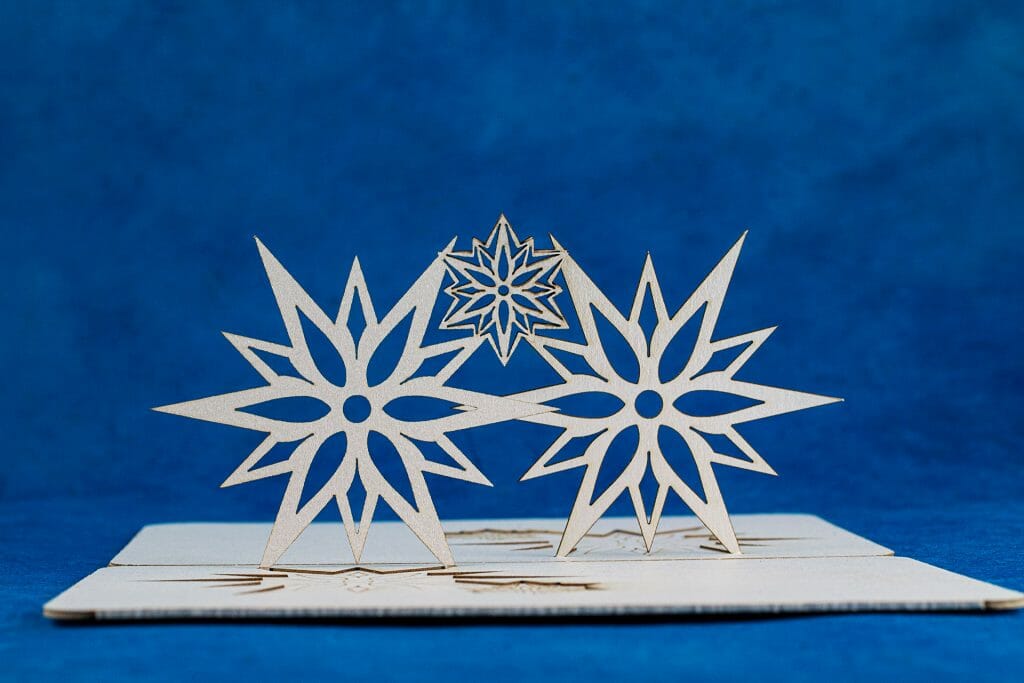

This is an update to my last post on modeling Celtic knots in Nomad Sculpt and creating depthmaps in Blender to carve with laser engravers and CNC machines. A newer feature in Nomad Sculpt makes it possible to export a depthmap directly, without having to go through Blender. A checkbox option in the debug menu (named “Heightmap”) switches to a depthmap view, which can be exported as a render. For best results, use a bitmap editor to spread the dynamic range.

I made a short video with a walkthrough: