Hex Chonk Box

I made some hardwood gift boxes for the 20-sided dice I made, and adorned them with custom silver Celtic knotwork medallions.

Continue readingI made some hardwood gift boxes for the 20-sided dice I made, and adorned them with custom silver Celtic knotwork medallions.

Continue readingI came up with a fairly simple workflow for creating 3D models of Celtic knots, used those to create depth maps and, used the depth maps to do 3D carvings on a laser (Glowforge) and a desktop CNC machine (Nomad 883).

Continue reading

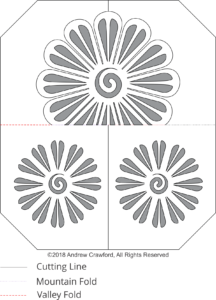

I have been having fun making these 180º open twisted crest style origamic architecture pop up cards. This is a clever technique and, I wanted to invite you to join in the fun. This post includes patterns for my new Flower Crest design, suitable for production on a laser cutter, a craft CNC cutter or, by hand.

Most people will have to actually make one of these cards or watch the folding video to get how it works. I originally spotted this technique used for several patterns in Keiko Nakazawa’s 2006 book 3D Pop-Up Greeting Cards (link in the resources section below) and, abstracted it to make my own designs. Rather than gluing to backing cards, I prefer to develop other approaches like what I have done here.

Settings for your cutting machine, whether CNC or laser, will vary depending on your machine, the specific paper stock you are using and other factors.

The paper I used for my cards was 0.014″ thick 105lb cover stock.

On the Glowforge, I used a speed of 500 and power of 72 for the cut lines and a power of 18 for the mountain fold lines. I scored the valley fold lines on the back by hand with a craft knife. If you are a Glowforge user, you likely have some experience dialing in settings for a particular material. I color-coded the file so that the GFUI will separate and order the operations on import.

27 July 2019 update: I’m seeing less smoke deposition with lower power and slower speed. I have switched to using 250 speed and 36 power.

My settings for each operation for the Gazelle cutter are in the MTC file as layer descriptions (D is depth setting on my adjustable blade holder, V is velocity and F is force). Those will probably be mostly useless unless you are also using a Gazelle cutter with an adjustable blade holder. If you are a craft cutter user, you are likely used to sorting out settings for a given stock. The layers are in the order you should cut them. The last two layers are the backing card (one score and the cuts).

Excited to un-box and set up new equipment for the stud.io today! 3D printing gets all the buzz but, CNC milling machines can do amazing things and, are not limited to plastic. If you are curious, you can read more about the machine at Carbide3D’s site. They also have some videos of the machines in operation. The wooden Lego bricks are especially cool. I have some reading to do before I can do much with this but, it’s very exciting.