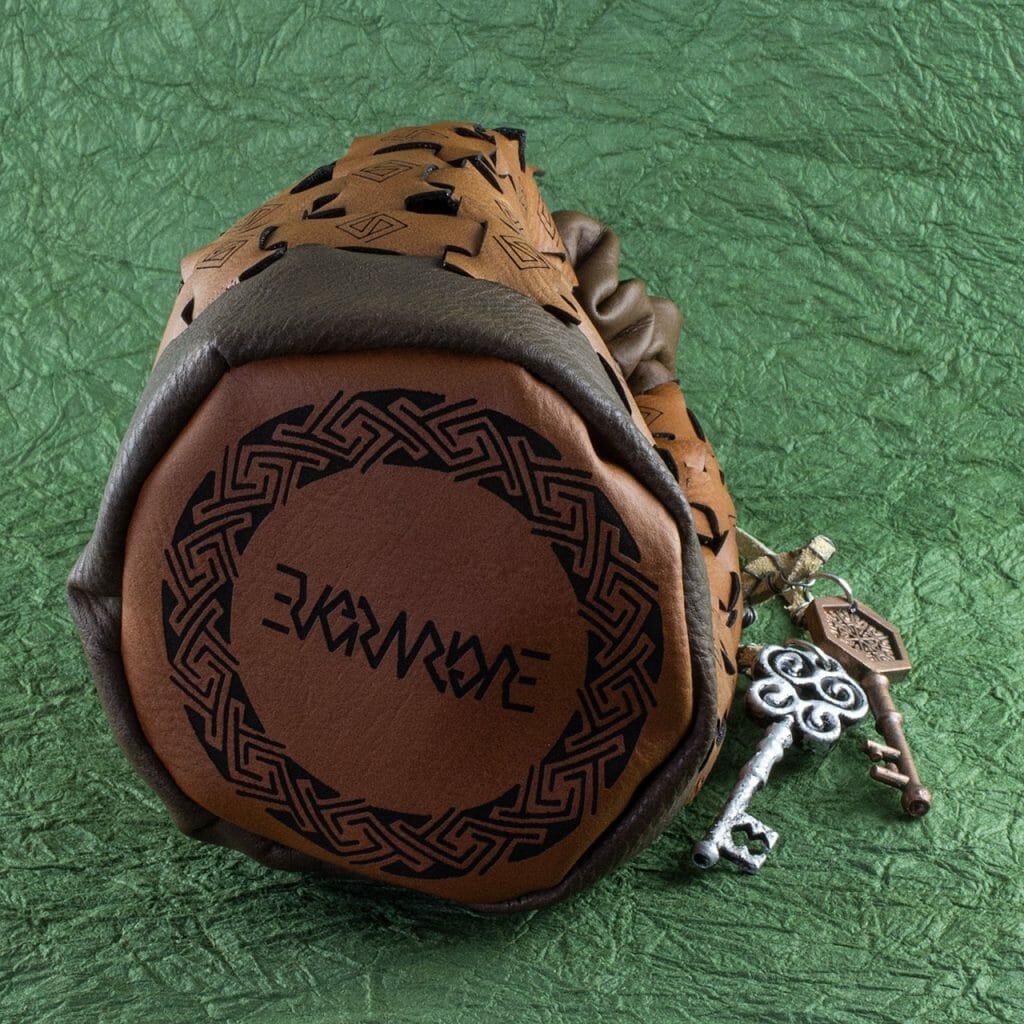

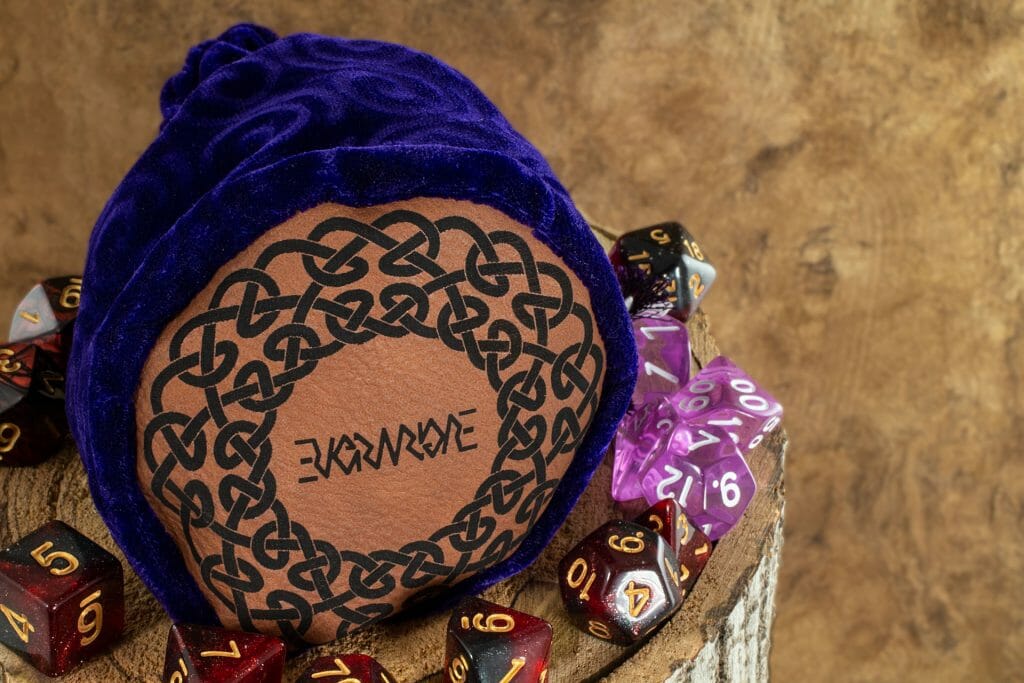

Drawstring Key Bag

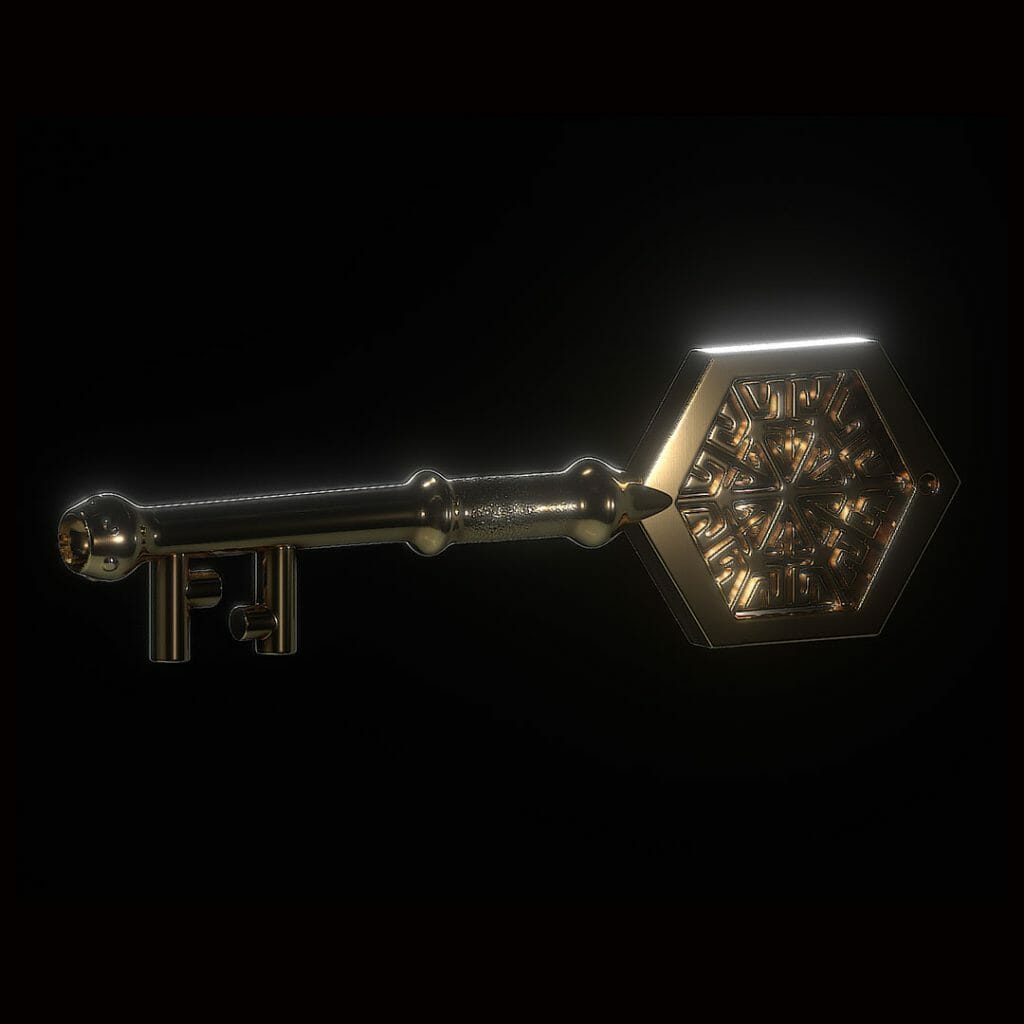

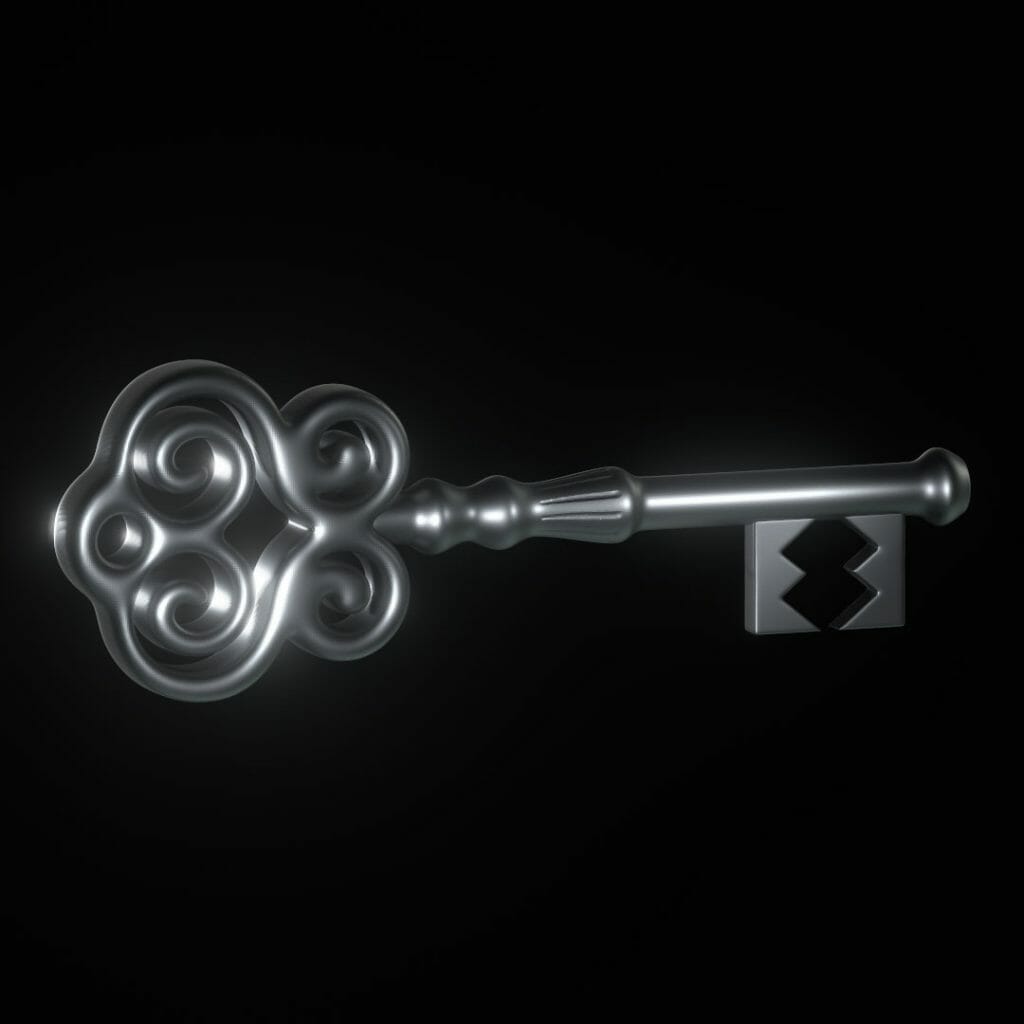

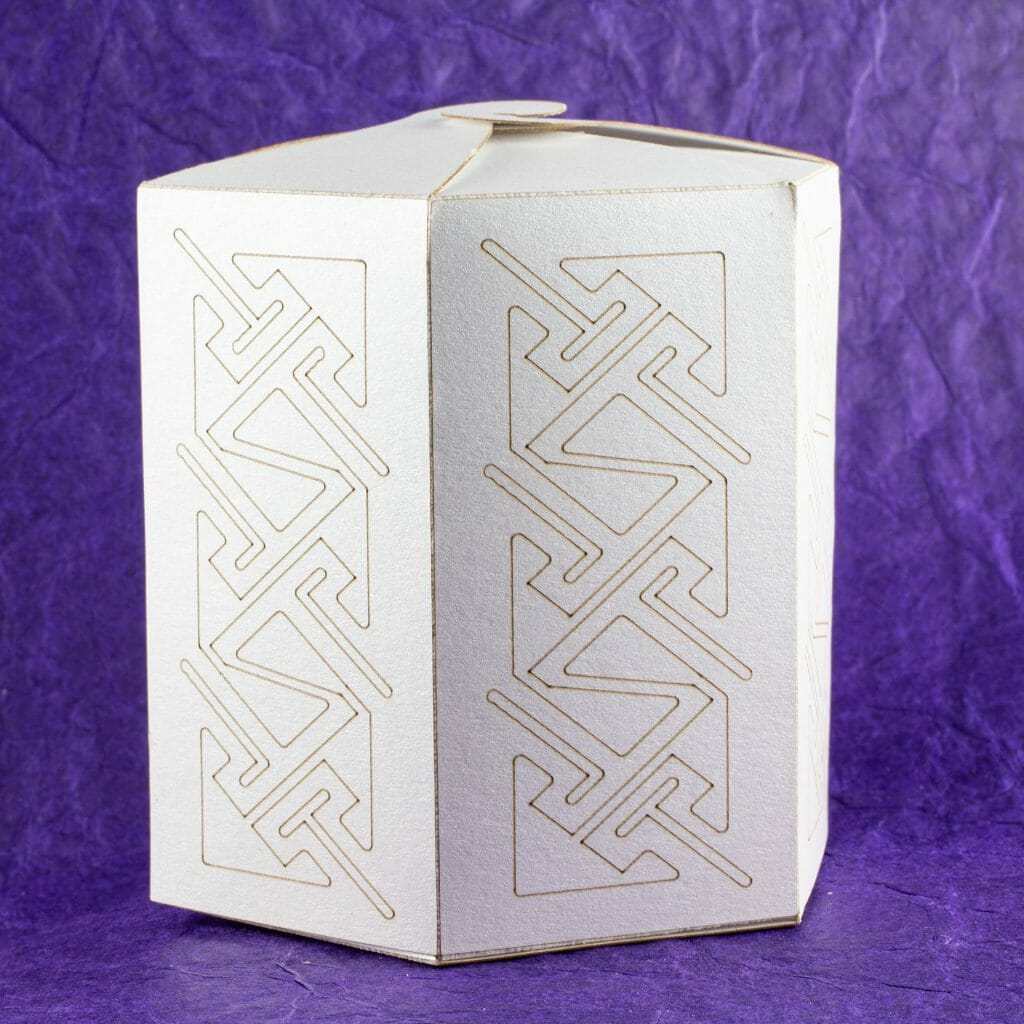

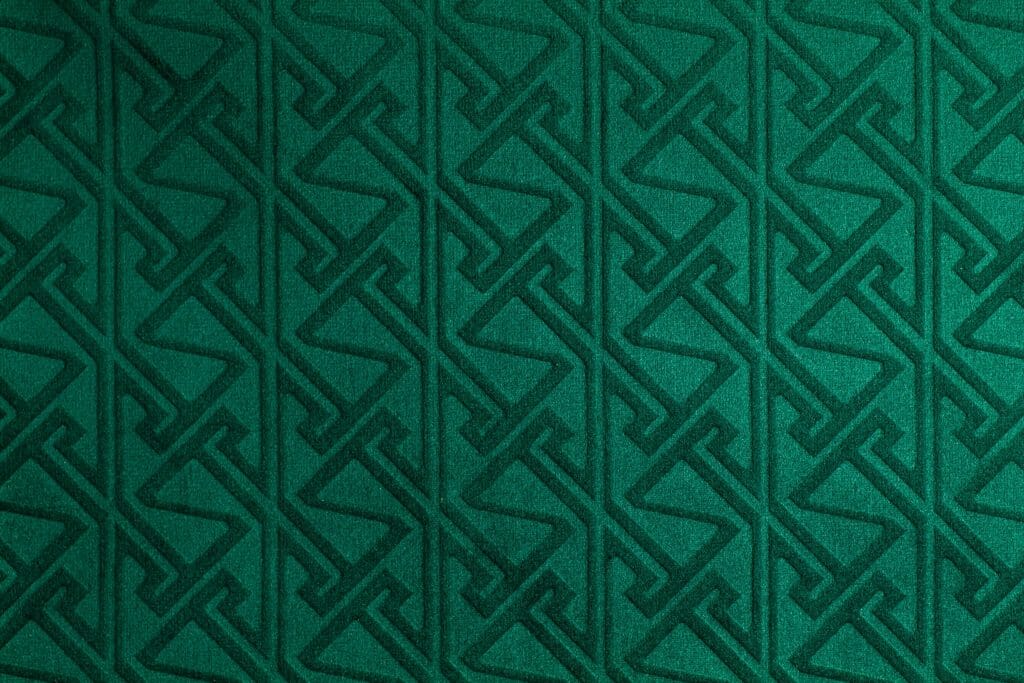

This scrap (faux) leather bag with a Celtic key theme is an initial exploration of a technique for using small scraps of leather or similar material leftover from other projects. I thought the tiles would be fun with a minimal Celtic key pattern motif in the center of each, then leaned into the theme with a circular key pattern ring on the bottom and, some 3D printed key, sculpted in Nomad Sculpt.

The SVG for the “leather locker” tile is linked below. You will likely want to adjust the slot height to match the thick ness of the material you are using. Let me know if you use it to make anything interesting!

This file is for personal, non-commercial use only. Note that, by referencing these, you are agreeing to release any variations you create under identical terms.